Pharmaceutical challenge: Alfa Laval helps secure a safe and sustainable water system

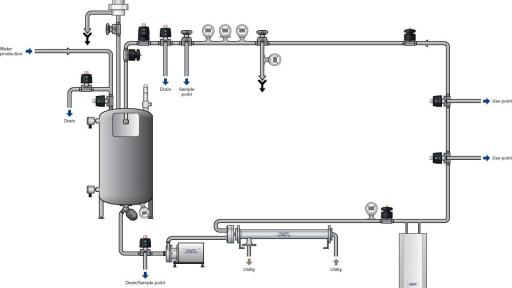

Pharmaceutical water systems ensure the safe, continuous and efficient operations of the pharmaceutical manufacturing facilities as well as the quality of the final end products. It is therefore critical to design pharmaceutical water systems (Image 1) to prevent conditions that compromise water quality by providing continuous recirculation at turbulent flows and no dead legs. Alfa Laval can supply hygienic equipment with proper design and quality that can help address challenges involving potential contamination, rouge, energy use and environmental emissions as well as issues involving installation, validation and maintenance.

Rouge - Involves the precipitation and spread of fine red-brown ferric oxide or hydroxide particles from the place of origin to associated systems. It can often be found in circulation pumps, diaphragm valves and inside tanks equipped with static spray balls.

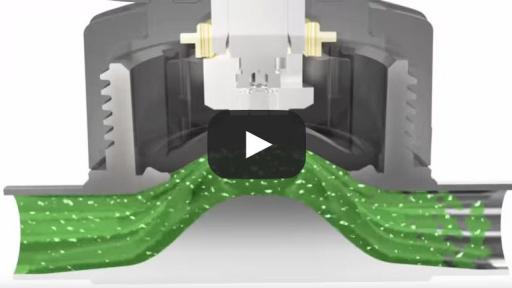

Biofilm - Populations of live microorganisms as well as dead microbial cells can form a layer, of biofilm, on the surfaces of pharmaceutical water system equipment. Biofilm buildup poses contamination risks.

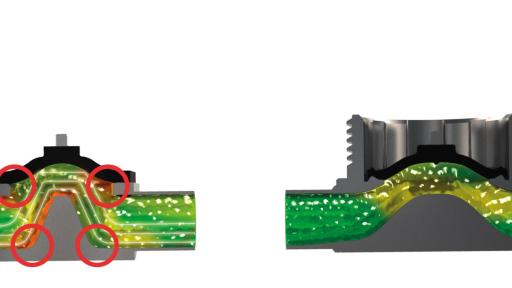

Sustainability - Maintaining continuous circulation and high temperatures in hot water systems is expensive and energy-intensive. Reducing energy use by selecting the right pumps, valves and heat exchangers (Image 4) can deliver energy savings.

Safe and easy installation, validation & maintenance - Ensuring proper installation, validation and maintenance of water systems is a business imperative for the pharmaceutical industry. These are a very time consuming tasks when you find yourself to be very dependent on the quality of the equipment and documentation delivered by your equipment supplier.

Multimedia Gallery

Summary

To minimize the above challenges:

- Use high-grade stainless steel with good surface finish quality to minimize rouge.

- Design systems and select hygienic equipment without dead legs, crevices, pockets or difficult- to-clean areas where stagnation can occur. The Alfa Laval Unique DV-P UltraPure is designed without any dead legs (Image 2) reducing biofilm buildup.

- Attention to detail pays off when selecting equipment for a distribution loop. Reducing energy use by selecting the right pumps, valves and heat exchangers can deliver energy savings. Alfa Laval LKH pumps are robust, reliable and energy-efficient pump. Be sure to size the pump correctly; oversizing the pump wastes energy (Image 3).

- Alfa Laval Q-doc documentation provides full transparency of all product contact parts, making it easy to validate thereby ensuring a smooth qualification and validation process.

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

Vist our web pages:

www.alfalaval.com/pharmawatersystems

www.alfalaval.com/pharmawatersystemschart

Contact

For more information about this article contact:

Chantra Trithara

Central Communications Coordinator

Alfa Laval

+46708557691

[email protected]