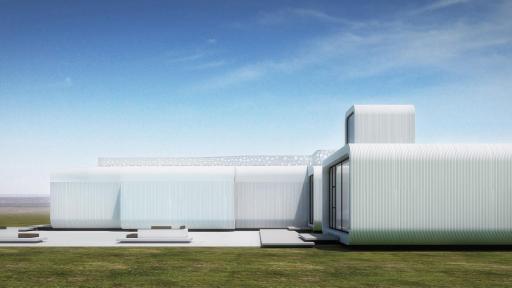

Dubai to build world’s first 3D printed office

Dubai, June 30, 2015: Plans have been revealed today in Dubai for the world’s first fully functional 3D printed building, an ambitious move that will establish the UAE’s position as the global centre of technology in architecture construction and design.

“This building will be a testimony to the efficiency and creativity of 3D printing technology, which we believe will play a major role in reshaping construction and design sectors. We aim to take advantage of this growth by becoming a global hub for innovation and 3D printing. This is the first step of many more to come.” H.E Excellency Mohammed Al Gergawi , UAE Minister Of Cabinet Affairs and The Chairman of UAE National Innovation Committee said on the this occasion.

The building will be located close to the ‘Museum of the Future’, launched earlier this year in Dubai, and will act as temporary headquarters for its staff. It will be approximately 2,000 square feet in size and will be printed layer-by-layer using a 20-foot tall 3D printer, then assembled on site in a matter of weeks. All interior furniture, detailing, and structural components will also be built using 3D printing technology. This will make it the most advanced, fully functional 3D printed building to date.

The project is the first major initiative of the ‘Museum of the Future’ and is part of a larger partnership between Dubai and WinSun Global - a joint venture between Chinese 3D printing technology firm WinSun and international investors - along with leading global architecture and engineering firms Gensler, Thornton Thomasetti, and Syska Hennessy.

Its design is based on in-depth research about the requirements of future work and represents the latest thinking in workplace design. The space is open and flexible, allowing for a range of uses and team sizes, and will bring together professionals, community members, and experts through a mix of public and private events. It will also feature a small digital fabrication facility and a 3D printing exhibition space.

The project marks the beginning of an important transformation in the construction and design sector; the shift to 3D printing and digital fabrication. Although long tested in labs, 3D printing technology is rapidly coming of age. This project will be the most advanced 3D printed structure ever built at this scale and the first to be put into actual use.

Experts estimate that 3D printing technology can reduce production times by 50 to 70 per cent, reduce labour costs by 50 to 80 per cent, and can save between 30 and 60 per cent of construction waste. These savings translate to enhanced productivity, higher economic return, and increased sustainability.

Gallery

Related Links

Museum of the Future WebsiteTranslation

ArabicMalay

Japanese

Chinese Simple

Chinese Traditional

French

German

Spanish